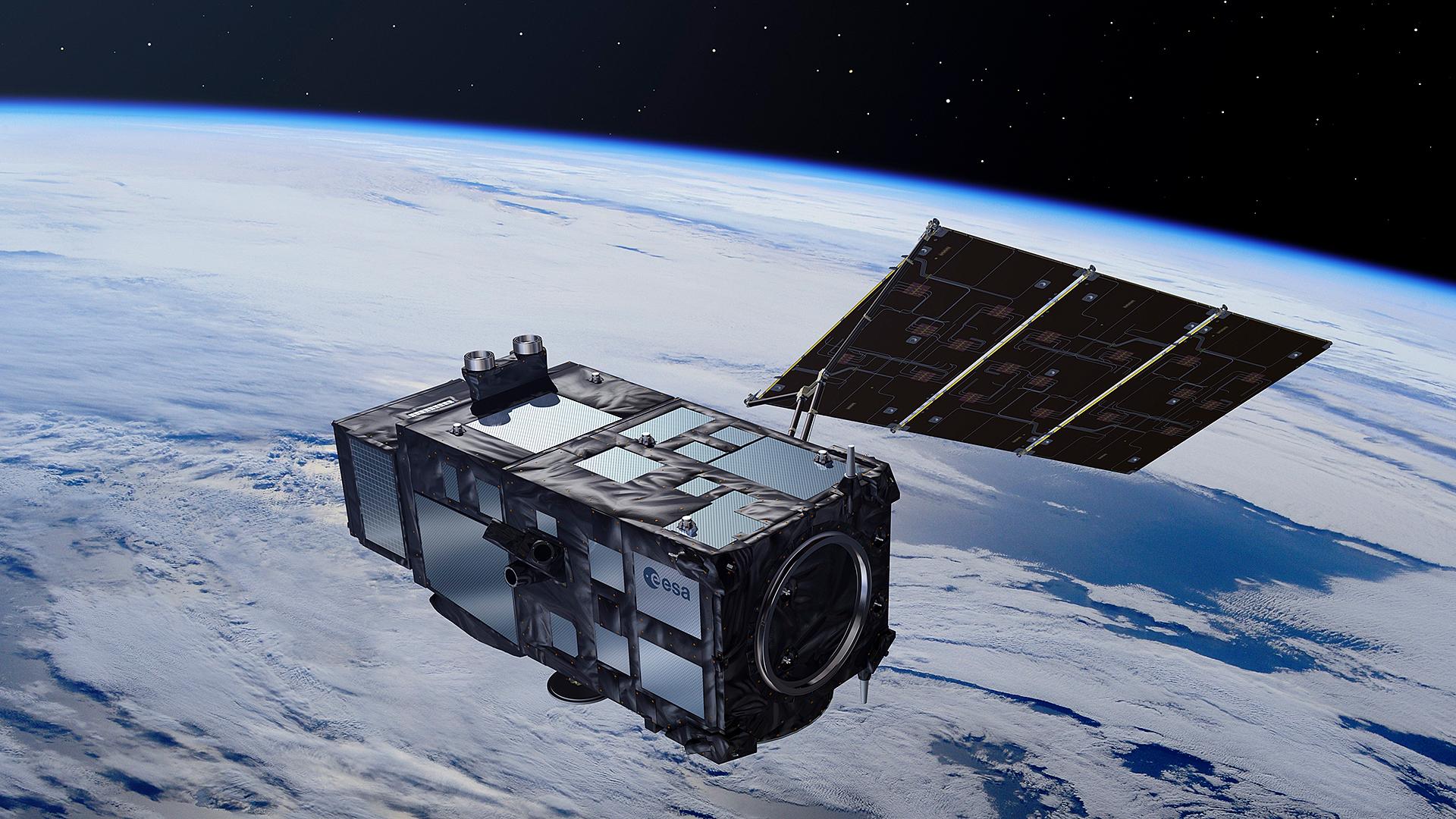

Aerospace & Defense

Advanced Multiphysics Simulation: AI-Integrated CFD & FEA for Aerospace & Defense

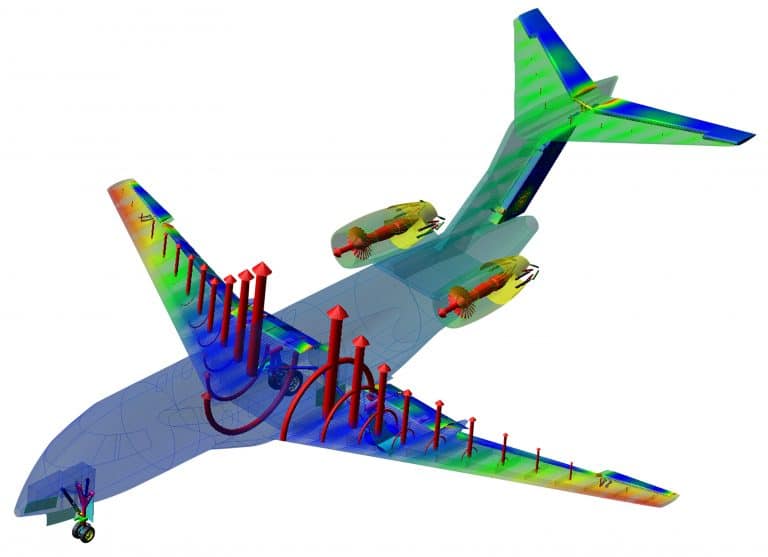

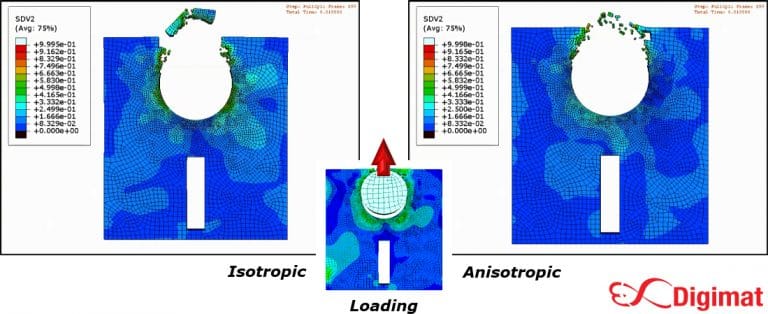

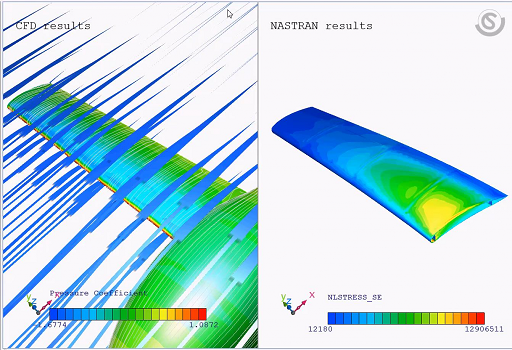

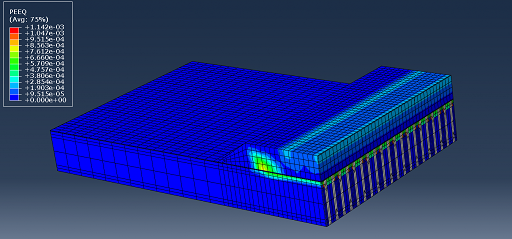

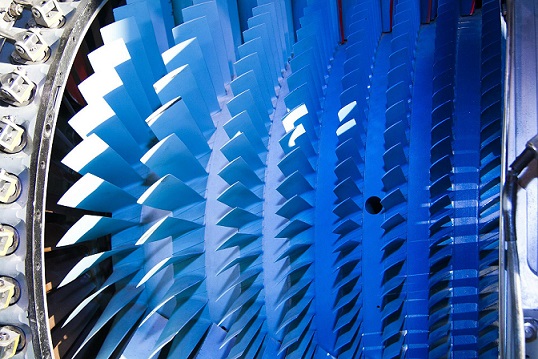

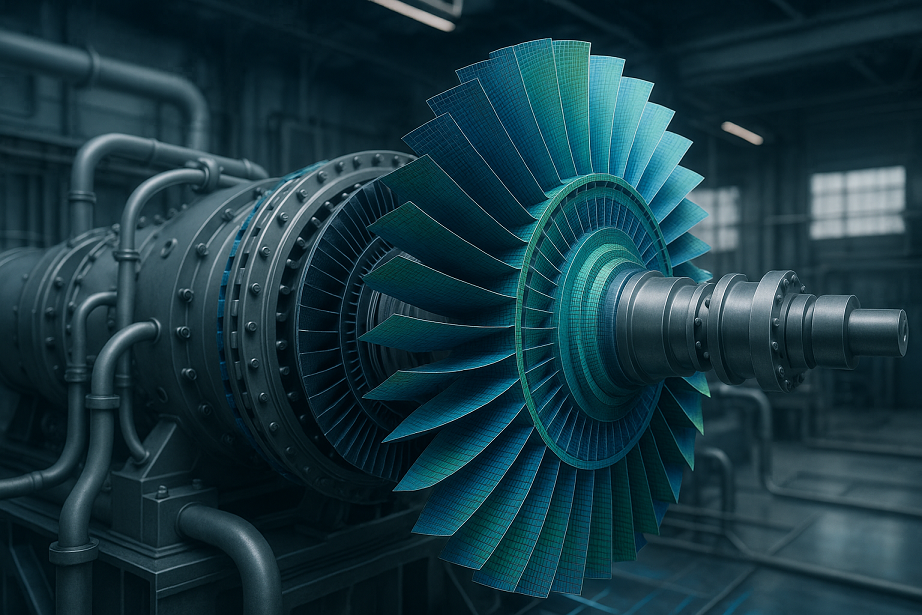

In the Aerospace and Defense industry, FEA is used to analyze the stress, deformation, and vibration of aircraft components, such as wings, fuselage, landing gears, and engine parts. FEA helps engineers optimize the design of components and reduce the weight of the structure without compromising its strength and durability.

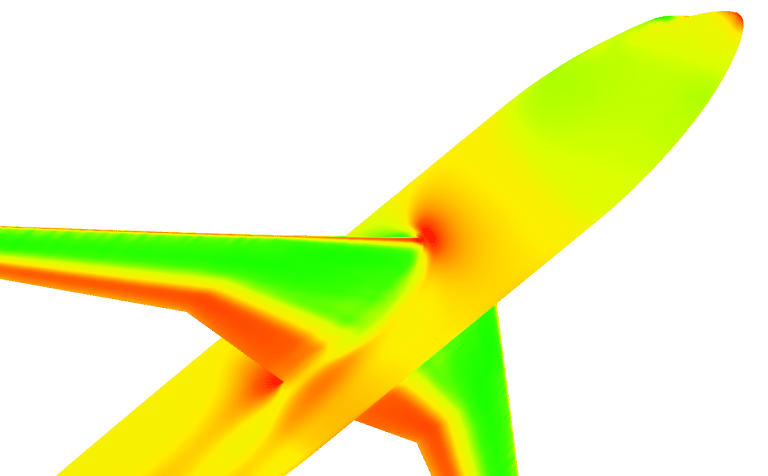

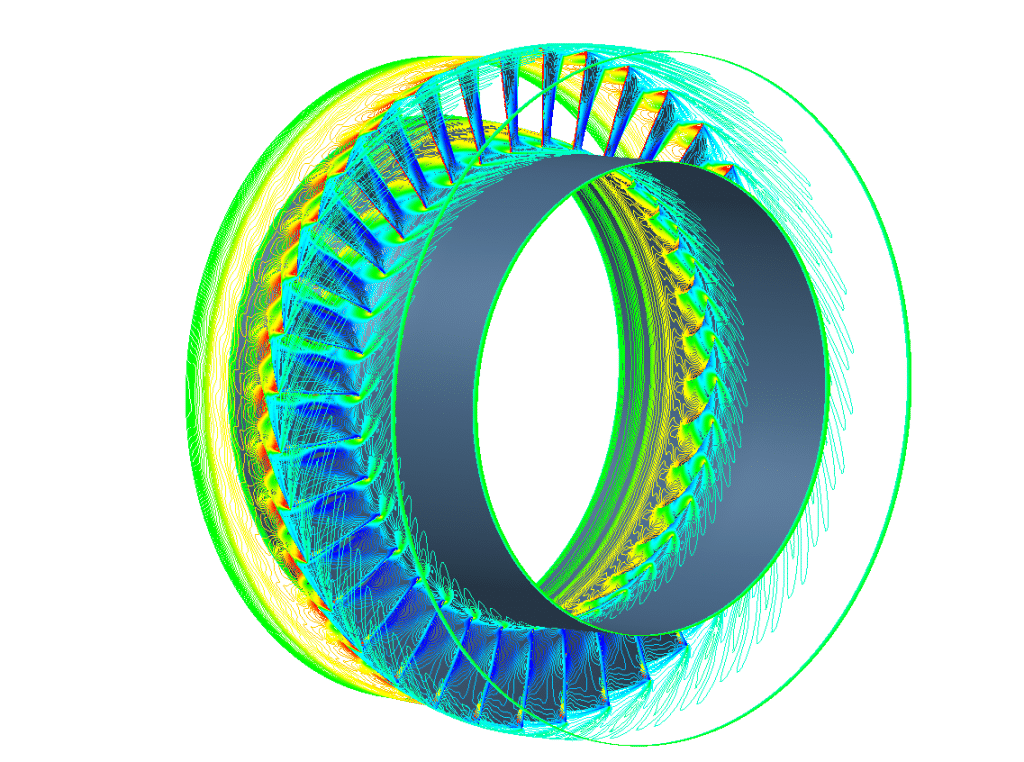

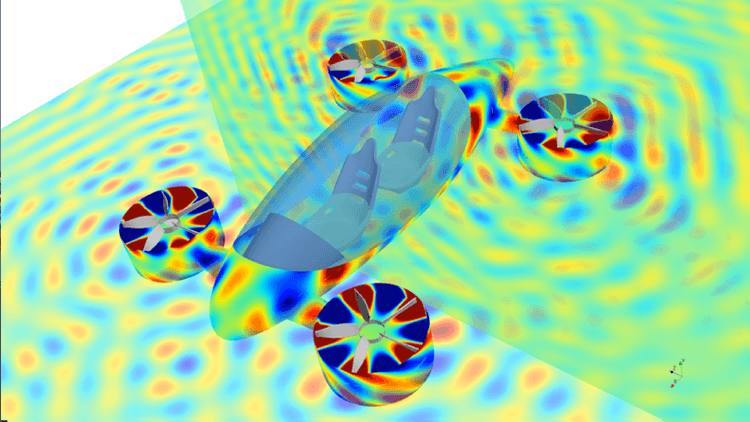

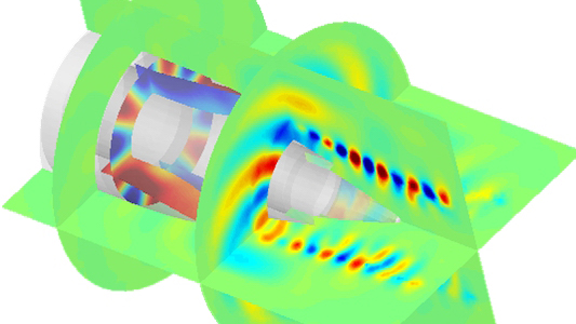

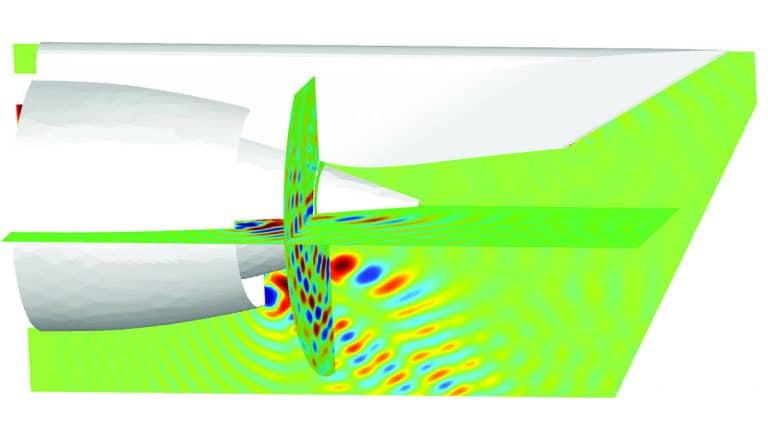

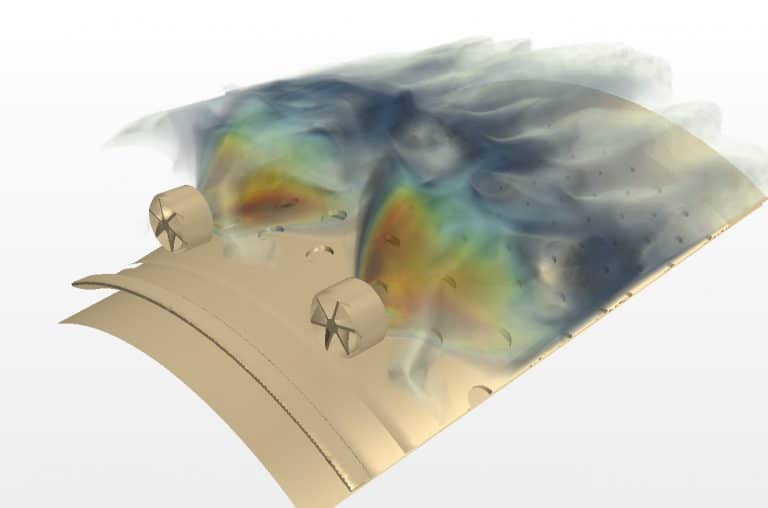

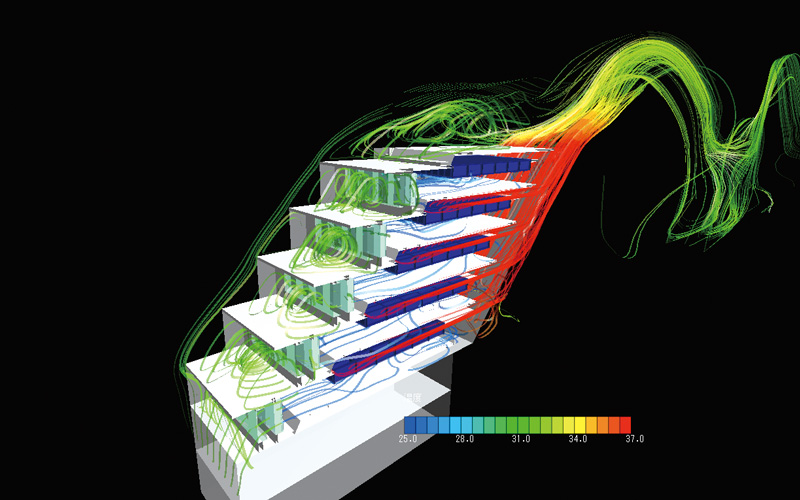

In the Aerospace and Defense industry, CFD is used to analyze the aerodynamics of aircraft, missiles, and rockets, as well as the thermal behavior of engine components. CFD helps engineers optimize the design of the airframe, wings, and propulsion system to reduce drag, increase lift, and improve fuel efficiency.

Both FEA and CFD simulations can help Aerospace and Defense companies to increase production efficiency, maintain high-quality products, and reduce production costs by reducing the number of physical prototypes needed, identifying potential design flaws early in the development process, and optimizing the design for performance and cost-effectiveness. By leveraging these simulation technologies, Aerospace and Defense companies can stay ahead of their competitors and deliver better products to their customers.